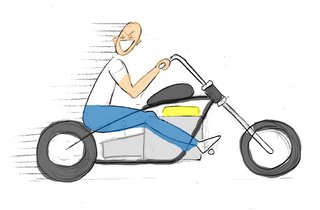

Its amazing how you can get so focused on the details of a job sometimes that you forget to stand back and see if the bigger picture is still as you planned in your initial vision.

Hugh came over today, and the sun came out (it always does where-ever Hugh goes) and so it seemed like a good excuse to get the Trike out of my pokey garage so that i could get better all round view of progress so far.

We shuffled the engine and front end back and forth by a half inch here and a mill or two there. We sat in the seat and jacked that up and down. We imagined what different handle bars would feel like.... and all in all, it felt good - I think im still on the right track.

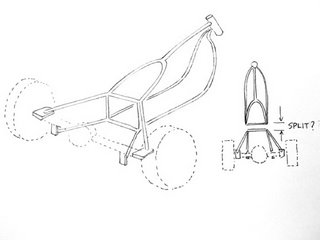

One design objective is to ensure that I keep the length of the vehicle short enough to be in beautiful proportion (many trikes appear to be too long to me) - but to achieve this the headstock has to come in close to the engine block meaning that the radiator would have to sit outside (in front) of the two front frame tubes (i'd ideally fit the rad in between them to keep things tidy). As we jiggled the bits back and forth, I used the word "compromise"! Hugh was quick to pick me up on it.... but that now leaves me with some head scratching and fine details to work out if im going to keep it short AND fit the rad in the frame as i want.

The other point that raised its head as we stood around the front end was; just how much of an angle do the forks have to rotate through while turning (it has an impact on where i weld the frame to the headstock) - so Hugh is going to have a measure of the rotation on his own bikes

There is heaps of design work to do still, but im confident and very happy that i am going in the right direction

l turn around.

l turn around.

.jpg)

.jpg)